Dual Modular Femur

The Future of Revision Hip Replacements

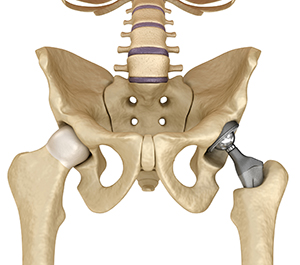

Hip replacement is a common solution for hip pain and stiffness caused by conditions such as osteoarthritis, rheumatoid arthritis, or fractures. In a healthy hip, cartilage covers the ball and socket joints, allowing them to move smoothly. If the cartilage gets worn down as seen in arthritis, it can cause a restriction in movement that leads to pain and stiffness. By removing parts of the pelvis and the femur, some of that pain and stiffness may be relieved. The most common type of procedure to accomplish this is a total hip replacement, or a total hip arthroplasty, where damaged sections of the hip is replaced with an artificial implant. Worldwide, more than 1 million total hip arthroplasties are performed each year.

Overtime, a hip replacement can fail for a variety of reasons, and a second operation may be needed to remove the original prosthesis, a process known as revision total hip arthroplasty. Hip dislocation is the number one cause for revision total hip arthroplasty, with the rate of dislocation after the first hip replacement as high as 28%. This problem has remained unsolved, and a lot of existing technology focuses on the socket to decrease the possibility of a hip dislocation.

Hip Replacement

Back in 2017, George Guild, MD, assistant professor in orthopedics, had a case where he needed to dislocate the patient’s hip to perform surgery. He had extreme difficulty dislocating the hip because every time he tried to move the femur to dislocate the hip, the patient’s prosthesis would rotate around the femur instead. “I remember thinking to myself, if we just had a prosthesis that was designed to do this it would be extremely stable,” noted Guild.

Guild has been a part of many hip implant design processes with companies, often focused on new socket designs. It was only natural for him to start working on novel ideas of his own. After seven or eight months of sketching, modeling the design, and eventually making a prototype of a prosthesis, Guild landed on the Dual Modular Femur. This design is a two-piece femoral prosthesis that can rotate.

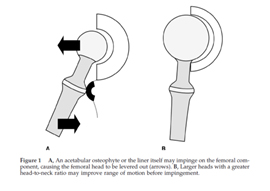

There are a variety of reasons why a hip might dislocate, this hip replacement innovation tackles one of the most common cause of hip dislocation, which is impingement. Impingement occurs when the head of the prosthesis hits the cup of the socket and pulls the ball out of the joint. Current hip replacement prosthetics rely on the use of a large femoral head to make it more difficult for the ball to leave the socket.

"With thousands of hip replacements occuring every year in the U.S., this innovation will have a far-reaching impact to improve many lives," said Mark Coburn, Director, Licensing at Emory OTT.

Dual Modular Femur

The Dual Modular Femur is designed to rotate so that even if the femoral neck hits the cup of the socket, impingement will not occur because of the ability of the femur to rotate. Research also suggests that the failure of the femoral part of the hip is primarily due to a contortion force applied to the prosthesis. This prosthetic design also alleviates this torsional strain because of the freedom of rotation allowed for the patient’s leg to move in a wider range of motion without levering the femur head out of the socket. This is the first prosthesis of its kind to have this design that allows for motion or rotation. Additionally, the design also allows it to overcome some amount of mispositioning of the acetabular cups, which can also contribute to hip dislocation.

After successfully cadaver testing, Guild is currently working to address additional biomechanical testing.

Techid: 20040

Read our technology brief